CURRENT MONITOR RELAYS

- Home

- Our Products

- Protection Relays

- CURRENT MONITOR RELAYS

Single Phase

KEW-Current Monitor Relays

Features of KEW-AVM-IP:

- Display:4-digit bright LED display

- Monitored Parameters: Current (True RMS), Phase Sequence, Reverse Current, Phase Loss, Unbalance Detection

- Protection Features: Under Current, Over Current, Phase Loss, Phase Reversal, Unbalance,

Reverse Current - Relay Output: One Relay Output (2A rated) available for contactor tripping or

external fault indication

Specification of Current Monitor Relay

- Electrical Characteristics

- Display Characteristics

- Mechanical Characteristics:

- Environmental Characteristics

- Metering Standard

- PARAMETER

(Current): R Phase, Y Phase, B Phase, Average - Relay Contact :

2AMPS , 250V AC POTENTIAL FREE - Auxiliary Supply: 150-300V AC, 45-270V AC/DC, 19-90V AC/DC

- VA Burden:

Auxiliary Supply: <1.5 VA

Current Input: <1.0 VA - RMS Current

Input: 50mA – 10A (CT set.) (Accuracy: – ±0.5%FS +1 dgt.) - Relay Output: 1 Relay Output (2A @ 250V AC), for tripping or alarm signaling

- Display: 4-digit bright LED display

- Indications: Error Code Display, Fault LED Indicators

- Mounting Type: Panel Mount

- Faceplate: Polycarbonate Transparent

- Case/Housing Material: FR-ABS Black

- Connectors/Terminal: Nylon 666, 33%GF

- Mounting Clamps: Sturdy, Moulded Glass filled nylon with screws

- Working Temperature: –10°C to +55°C

- Storage Temperature: -10°C to 60°C

- IEC62052-11

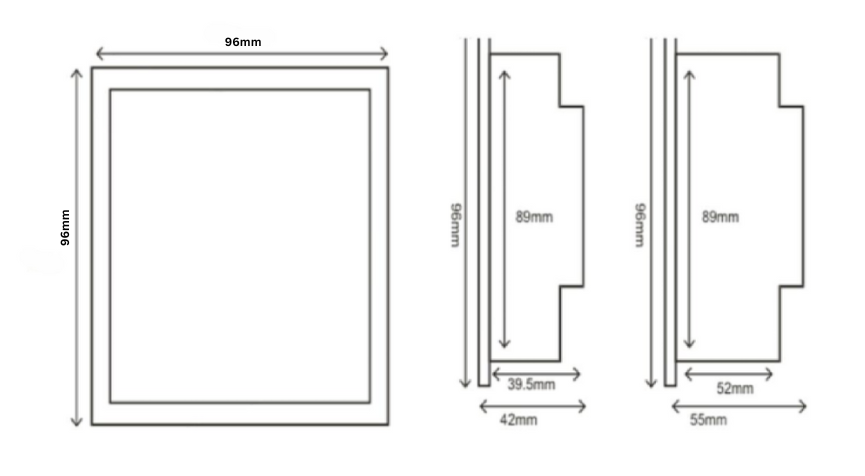

Panel Cutout Dimensions

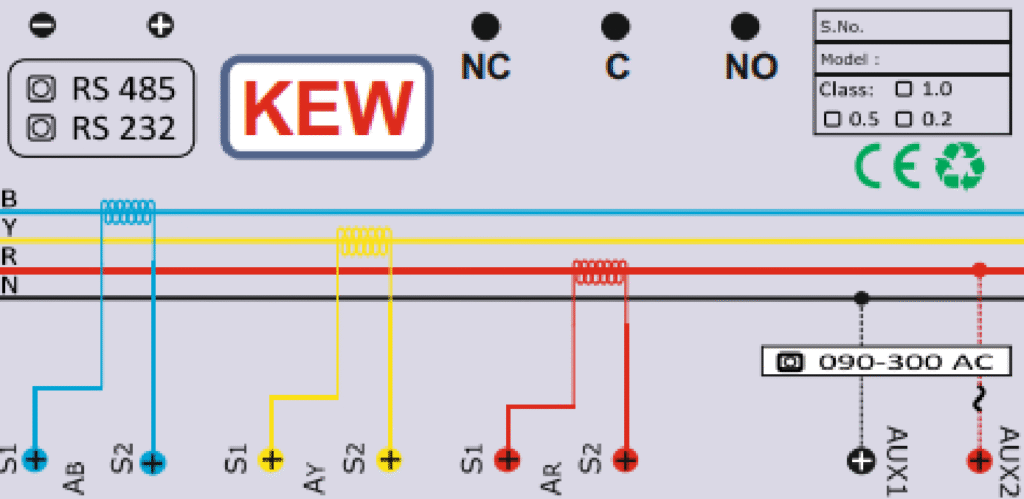

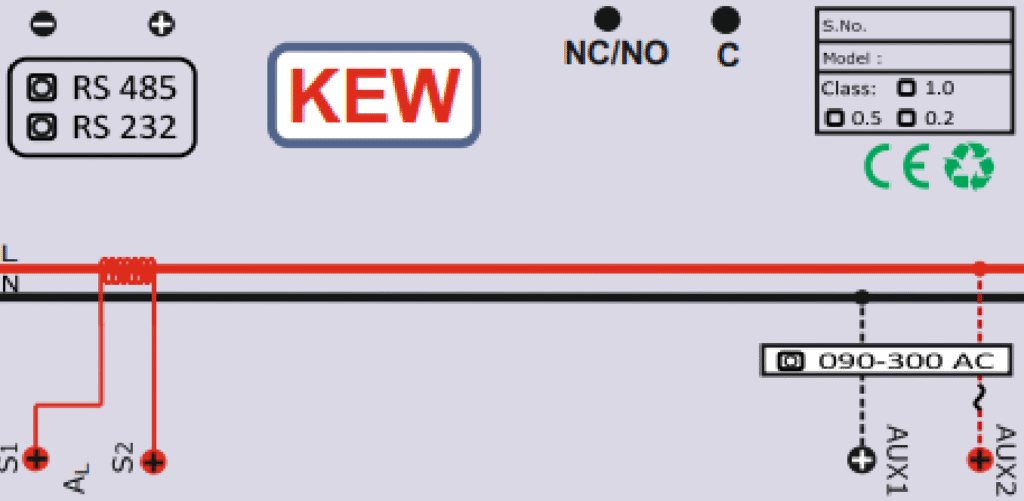

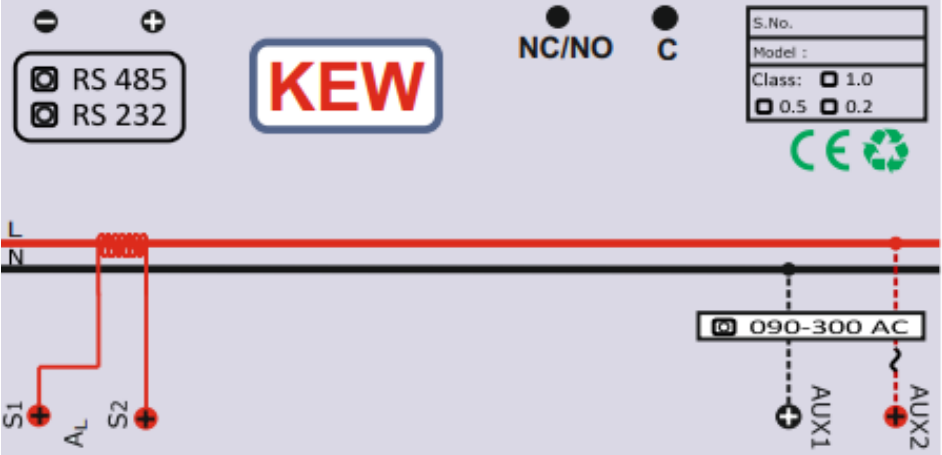

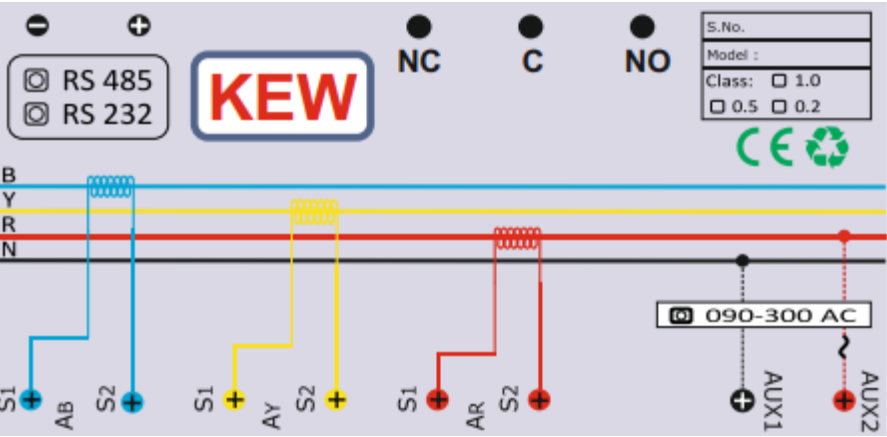

Terminal Connection

Applications and Industries where it is used

Building Management Systems (BMS)

Where: In BMS-controlled electrical panels that manage HVAC motors, water pumps, escalators, and other building equipment.

Why: To continuously monitor the operating current of connected loads and detect abnormal conditions like overcurrent (overload, mechanical jam) or undercurrent (belt breakage, dry running) so the BMS can trigger alarms or shut down the equipment — ensuring energy efficiency, equipment protection, and reduced maintenance downtime.

Motor Control Panels

Where: In Motor Control Panels (MCPs) for pumps, conveyors, compressors, and industrial fans, monitoring the load current of each motor circuit.

Why: To detect undercurrent or overcurrent conditions caused by issues like motor overload, mechanical jamming, belt breakage, or dry running, and trigger alarms or shutdowns — ensuring motor protection, process reliability, and reduced maintenance costs.

OEM Electrical Panels

Where: In OEM-manufactured electrical panels for machinery such as CNC systems, packaging lines, elevators, or HVAC units.

Why: To monitor motor or equipment load current and detect anomalies like overloads (mechanical jamming, bearing failure) or underloads (belt slip, no-load running) so the system can trigger protective shutdowns or alarms — ensuring equipment longevity, reduced service calls, and prevention of costly breakdowns in customer installations.

Commercial Sub Metering / Retail Malls

Where: In commercial submetering panels and retail mall tenant distribution boards that supply power to individual shops, kiosks, food courts, and common-area facilities.

Why: To monitor the load current of connected circuits and detect overcurrent (caused by equipment overload or short circuits) or undercurrent (indicating idle or faulty loads), enabling facility managers to take corrective action — ensuring tenant equipment protection, energy efficiency, and prevention of costly power disruptions in high-footfall areas.

Ordering Information

| Model | Accuracy Class | Display & Protection | Aux Supply |

|---|---|---|---|

| KEW-CMR (SFL-964) | ±0.5% | 3 Phase Over & Under Current Protection | 150–300V AC, 45–270V AC/DC, 19–60V AC/DC |

| KEW-CMR(SFL-962) | ±0.5% | 1 Phase Over & Under Current Protection | 150–300V AC, 45–270V AC/DC, 19–60V AC/DC |

| KEW-CMR(SFL-964D) | ±0.5% | 3 Phase Over & Under Current Protection With Display | 150–300V AC, 45–270V AC/DC, 19–60V AC/DC |

| KEW-CMR(SFL-962D) | ±0.5% | 1 Phase Over & Under Current Protection With Display | 150–300V AC, 45–270V AC/DC, 19–60V AC/DC |