AC MONITOR PROTECTION RELAYS

- Home

- Our Products

- Protection Relays

- AC MONITOR PROTECTION RELAYS

Single Phase

KEW-AC Protection Relays

Features of KEW-AVM-IP:

- Display: 3-row, 4-digit bright LED display

- Monitored Parameters: Voltage (RY, YB, BR), Current, kW, Power Factor, kWh, kVARh,

Hours, Run Hours, Rotor Earth Fault - Protection Features: Under/Over Voltage, Over/Under Current, Earth Fault, Phase Reversal,

Current Imbalance, Dry Run, Phase Loss - Programmability: CT/PT Ratio Programmable, Settable Trip Values, 2 Relay Outputs (user-configurable), MODBUS RTU support (optional)

- Size: 96×96

Specification of AC Monitor Protection Relay

- Electrical Characteristics

- Display Characteristics

- Mechanical Characteristics:

- Environmental Characteristics

- Metering Standard

- Measured

Parameters: RMS Voltage (20–600V), RMS Current (0.020–10.00A), Active

Power (0.030–6.000kW), Apparent Power (0.030–6.000kVA),

Reactive Power (0.030–6.000kVAR), Power Factor (0.3–1.0,

Lag/Lead), Line Frequency (45–65Hz), Active Energy (0–

999999.99kWh), Apparent Energy (0–999999.99kVAh),

Reactive Energy (0–999999.99kVARh) - Relay Contact :

2NOS-8 AMPS, 250VAC POTENTIAL FREE - Auxiliary Supply: 150–300V AC, 45–270V AC/DC, 19–60V AC/DC

- VA Burden:

Auxiliary Supply: <2.5 VA

Voltage Input: <0.2 VA/Phase

Current Input: <0.2VA/Phase - Impulse Withstand: 3.5KV for 1.2/50 micro second

- CT Range: CT Primary: 1A–50kA (AC Programmable),

CT Secondary: 0.5A–5A (AC Programmable)

- Display: 3-row, 4-digit bright LED display with Auto/Manual Scroll

- Indications: Error Code Display, Fault LED Indicators

- Mounting Type: Panel Mount

- Faceplate: Polycarbonate Transparent

- Case/Housing Material: FR-ABS Black

- Connectors/Terminal: Nylon 666, 33%GF

- Mounting Clamps: Sturdy, Moulded Glass filled nylon with screws

- Working Temperature: 0°C to 50°C

- Storage Temperature: -10°C to 60°C

- IEC62052-11

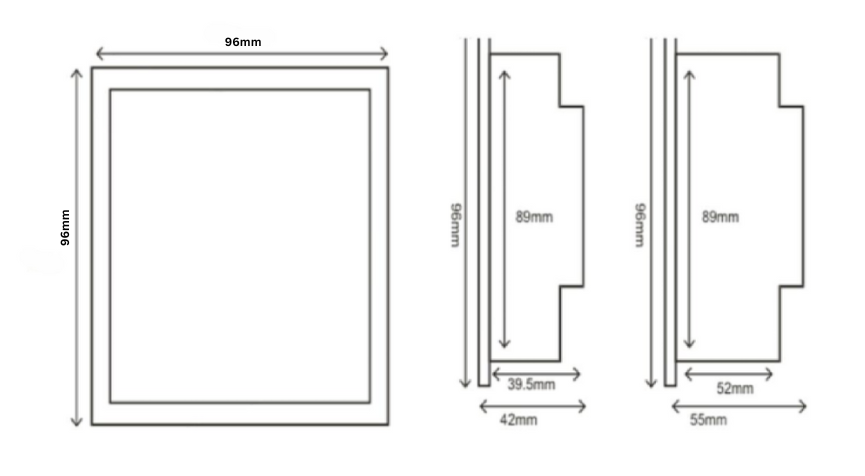

Panel Cutout Dimensions

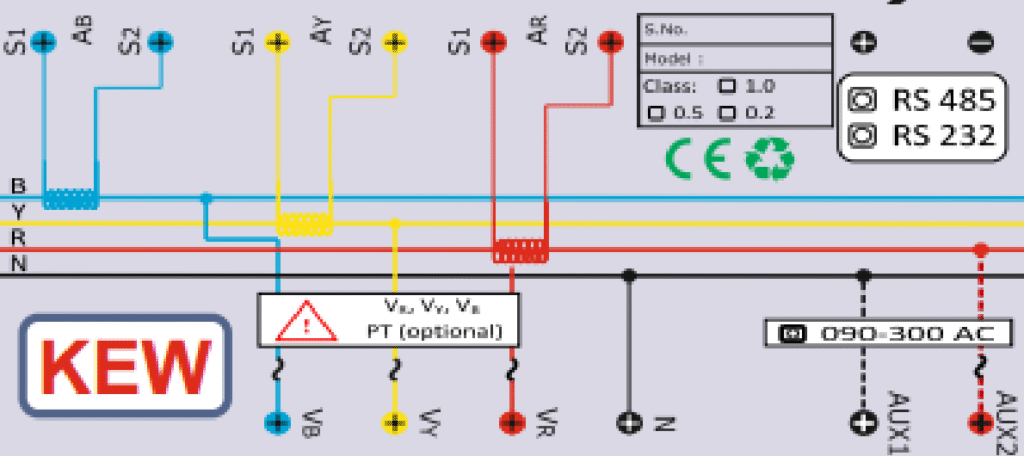

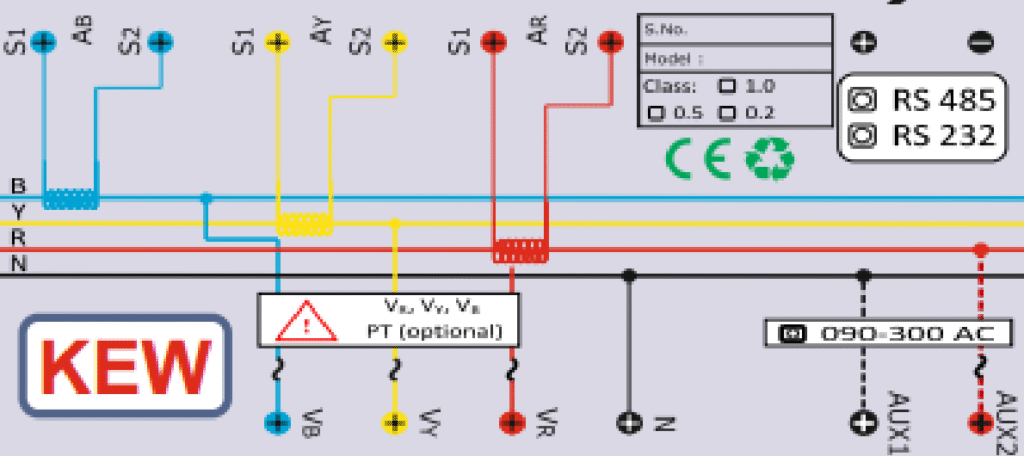

Terminal Connection

Applications and Industries where it is used

Building Management Systems (BMS)

Where: Inside the BMS-controlled main LT panel or HVAC/equipment control panels that distribute AC power to building systems.

Why: To protect motors, HVAC units, lighting circuits, and other critical loads from phase loss, voltage imbalance, over/under-voltage, or frequency deviations, preventing damage and ensuring uninterrupted building operations.

Motor Control Panels

Where: In Motor Control Panels (MCPs) for pumps, fans, compressors, and conveyors.

Why: To detect phase loss, reverse phase, voltage imbalance, or abnormal frequency and trip the motor circuit before faults cause winding damage, overheating, or unplanned downtime.

OEM Electrical Panels

Where: Inside OEM electrical panels of machinery such as packaging lines, CNC machines, lifts, and industrial ovens.

Why: To continuously monitor incoming AC supply quality and isolate the machine during abnormal voltage, phase, or frequency conditions, protecting sensitive components and reducing warranty claims or field failures.

Commercial Sub Metering / Retail Malls

Where:In commercial submetering panels and retail mall distribution boards feeding tenant shops, kiosks, and common-area equipment.

Why: To protect lighting, escalators, HVAC units, and tenant machinery from supply anomalies like phase loss, over/under-voltage, or imbalance, ensuring safety, reducing equipment downtime, and avoiding disputes over power quality issues.

Ordering Information

| Model | CT Input Range | Display | Aux Supply | Dimensions (MM) |

|---|---|---|---|---|

| KEW-MPR (96×96) | CT 1A–50kA / CT 0.5A–5A (Programmable) | 3-Row, 4-Digit LED | 80–300VAC / 24–240VDC (Universal) | 96×96 |