🔌 Reimagining Energy Meters with Edge AI

🔌 Reimagining Energy Meters with Edge AI

🌐 Introduction:

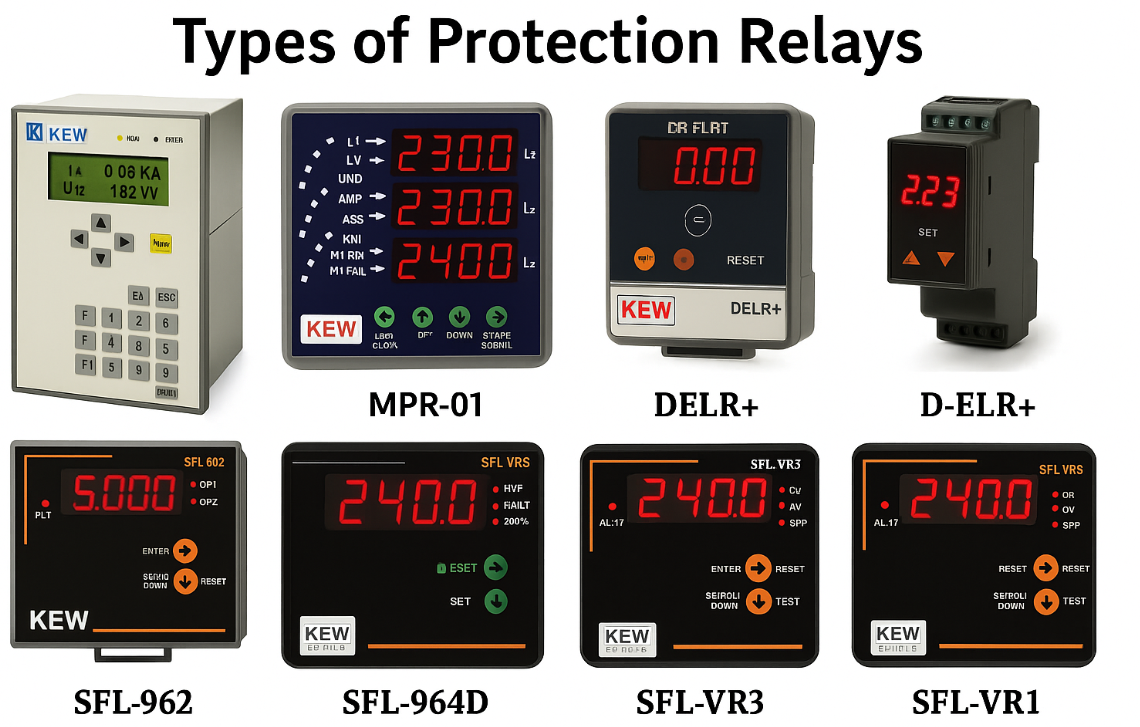

At KEW, we’ve spent decades building robust and accurate energy metering solutions for India’s evolving power infrastructure. But as energy systems become more complex — with renewables, storage systems, EVs, and automation entering the grid — the limitations of traditional meters are becoming clear.

We believe the next evolution in metering will be driven by Edge AI — and this blog is our open brainstorming journey to explore how it can revolutionize the future of energy intelligence.

🤖 What is Edge AI?

Edge AI refers to the ability to run AI models directly on embedded devices (like smart meters, gateways, or sensors) — without sending data to the cloud.

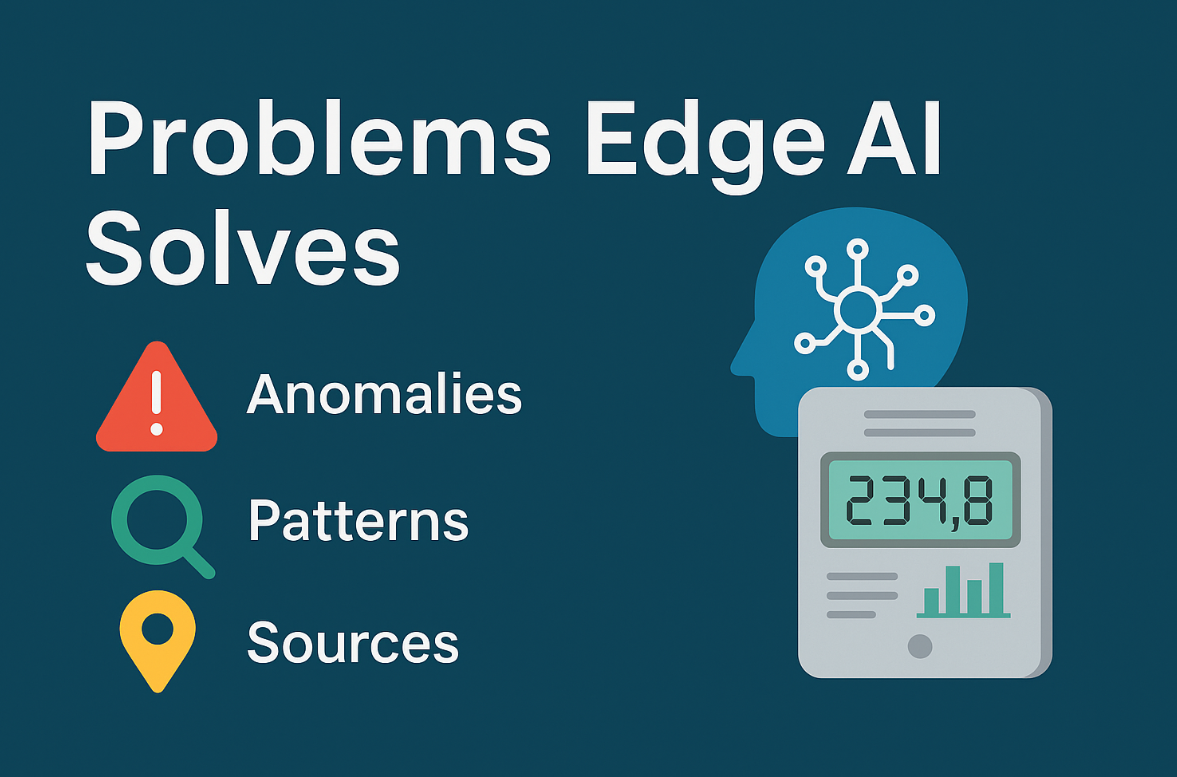

Instead of just collecting and sending data, an Edge AI device can:

Analyze data locally,

Learn from behavior over time,

Detect anomalies or events,

Take decisions or raise alerts — all in real time.

It’s like turning a passive device into a real-time intelligent assistant — compact, low-power, and secure.

⚠️ Why Traditional Energy Meters Fall Short

Traditional energy meters — even modern digital ones — are primarily data loggers:

They measure voltage, current, and energy,

Apply a few rules (e.g., if voltage > 250V, raise alert),

And send logs to a backend server or cloud platform.

But they don’t understand what’s happening. They can’t:

Detect unusual device behavior if values are still “within range”

Predict load before it spikes

Pinpoint the source of a problem (e.g., which appliance is faulty)

Alert on subtle signs of degradation or tampering

In a world that’s dynamic, distributed, and data-driven — this just isn’t enough.

⚠️ Real-World Metering Challenges Faced by KEW and the Industry

🔧 1. Undetected Electrical Faults and Irregularities

The Problem:

In both urban buildings and rural installations, electrical faults often do not immediately trip protective devices or cross set thresholds. For instance:

A loose neutral wire may only cause intermittent voltage drops.

Energy theft methods may cleverly avoid exceeding predefined current limits.

Overloaded circuits may show erratic but legal-looking current profiles.

Why It’s Hard for Traditional Meters:

Meters follow hard-coded rules: “If voltage > 260V, raise alarm” — but faults often happen within those limits.

Subtle fluctuations in voltage–current correlation go undetected.

There is no dynamic learning of what is “normal” for a given site.

Impact:

Faults go undetected until they cause failures.

False negatives increase risk of fire, equipment failure, or energy loss.

Site inspections are reactive, not data-driven.

📊 2. Lack of Load and Usage Intelligence

The Problem:

KEW meters (and others in the market) can record total consumption, but don’t know the behavioral signature of how that energy is used:

Which appliances are operating?

Are usage patterns typical for that time of day or day of week?

Has any unexpected or unknown device started drawing power?

Why It’s Hard for Traditional Meters:

They only record aggregate values — no load disaggregation.

No ability to compare live data to historical behavior patterns.

No classification or detection of new/unusual usage patterns.

Impact:

Operators can’t spot irregularities in energy usage in real time.

Meters can’t provide context-aware insights — they only show numbers.

Useful for billing, but useless for diagnostics or energy optimization.

🧭 3. No Clarity on Source of Disturbances

The Problem:

In industrial panels or mixed-use commercial buildings, power quality events like harmonics, surges, or voltage sags are often detected, but not diagnosed:

What device caused it?

On which phase?

Was it the new variable frequency drive (VFD)? Or the old UPS?

Why It’s Hard for Traditional Meters:

Harmonics or voltage dips are logged — but not attributed to any source.

No built-in AI model to correlate patterns to known equipment types.

No multi-channel AI inference capability at the edge.

Impact:

Maintenance teams waste time guessing and testing.

Poor power quality continues to degrade sensitive devices.

Downtime and service calls increase.

📉 4. No Forecasting for Energy Planning

The Problem:

Most KEW meters operate in real-time mode only. They show what’s happening now, but not what’s about to happen — like:

Will load increase significantly after lunch break in a factory?

Should batteries be charged in advance of evening load?

What’s the expected energy draw during a festival or event?

Why It’s Hard for Traditional Meters:

They don’t store enough historical context for learning.

No algorithms for time series prediction run at the meter level.

External platforms are needed — increasing cost and complexity.

Impact:

No demand shaping or intelligent load scheduling.

Missed opportunities for load balancing in solar/microgrid systems.

Increased stress on grid infrastructure during peak events.

⚠️ 5. No Predictive Alerts for Failing Appliances

The Problem:

Energy meters today cannot detect device degradation or predict failures:

Motors that slowly draw more current before failure

Refrigerators with compressors showing poor startup behavior

Fans or pumps with phase imbalance or bearing issues

Why It’s Hard for Traditional Meters:

They lack temporal context — can’t track subtle changes over time.

No AI model to distinguish between normal drift vs. failure signature.

No integration with asset health data or predictive analytics.

Impact:

Failures are detected only after breakdowns.

No early warning → higher downtime, maintenance cost, and frustration.

Businesses have no way to prioritize service or maintenance.

🔓 6. Security, Privacy & Offline Operation Limitations

The Problem:

Smart meters connected to the cloud face challenges:

Data privacy concerns (residential, defense, or infrastructure sectors)

Dependency on stable internet — which may not be available in industrial zones or remote areas

Latency of cloud-based analytics

Why It’s Hard for Traditional Cloud Solutions:

Data has to leave the meter → security risk

Remote locations → low connectivity

Real-time alerts → delayed response

Impact:

Utilities are reluctant to rely on cloud-only solutions.

Mission-critical decisions are delayed.

Meters remain “dumb” in critical offline conditions.

🔭 KEW’s Vision: Enabling Smart, Secure, AI-Driven Meters

While we’re still in the brainstorming and R&D phase, our long-term mission is clear:

To transform every KEW energy meter from a passive measurement device into an active intelligence unit — capable of learning, adapting, and protecting energy systems in real time.

We’re currently:

Evaluating suitable AI models for embedded MCUs

Mapping electrical problems to data signatures

Designing prototype architectures for field pilots

Exploring integration with secure firmware, DLMS, and local analytics

🧩 What’s Next?

In the coming months, we aim to:

Build proof-of-concept demos of Edge AI-based diagnostics

Collaborate with academic and R&D labs for model testing

Partner with OEMs and panel builders to identify pilot use cases

If you’re a system integrator, control panel OEM, industrial user, or researcher — we’d love to collaborate with you.

📣 Closing: Let’s Build the Future of Smart Metering — Together

At KEW, innovation is in our DNA. And with Edge AI, we see an opportunity to completely change how energy systems are monitored, understood, and managed.

This blog marks our first public step into that future — and we welcome partners, collaborators, and early adopters to join us on this journey.

👉 Reach out to us to explore how we can co-create India’s next generation of intelligent metering systems.